Widespan Development

Concept of roof module cross section as discussed on the 02-11-05

All notes below refer to diagram above

Pipe Mounting Edge

I figured an edge integrated into the extrusion to attach the ‘snow melt feed pipe’ and ‘cooling film feed pipe’ might be worth considering. This would save having to puncture the ‘bubble cavity closure baffle’. Maybe a plastic pipe fastener could be made to snap onto this edge. It would certainly speed up the erection.

Bubble Cavity Drain

If we are using soap solution as a cooling/collection film them why not have the bubble cavity drain into the bottom cavity where it can run into the returning gutter. Simple eyelets at the low point in bubble cavity would be sufficient as the returning flow would be very slow and low in volume. If we are running algae then this obviously wouldn’t work.

Relationship of Angles A and B

With no loading, in order for the tension to be equal in all three skins 2SinA = sinB (I think). For example: if A = 12degrees then B = 24.6degrees. Equal tension in all skins may not be necessary however being as we have variable loading. I don’t really understand the issues here, but I thought it would be worth mentioning. The maths seems to fit my intuitive feelings for the proportions, but what do artists know about engineering?

Supper Efficient Variation for Extreme Cold Climates

If another ‘closure baffle’ was installed in the bottom cavities then these cavities could also be used to contain bubbles at night. Using cold bubbles in the top cavity and warmer bubbles in the bottom. This however, would require twice as many bubble generators, but that’s all it would seem. The bottom cavity could still be used in cooling/collection mode during the day.

All notes below refer to diagram above

Pipe Mounting Edge

I figured an edge integrated into the extrusion to attach the ‘snow melt feed pipe’ and ‘cooling film feed pipe’ might be worth considering. This would save having to puncture the ‘bubble cavity closure baffle’. Maybe a plastic pipe fastener could be made to snap onto this edge. It would certainly speed up the erection.

Bubble Cavity Drain

If we are using soap solution as a cooling/collection film them why not have the bubble cavity drain into the bottom cavity where it can run into the returning gutter. Simple eyelets at the low point in bubble cavity would be sufficient as the returning flow would be very slow and low in volume. If we are running algae then this obviously wouldn’t work.

Relationship of Angles A and B

With no loading, in order for the tension to be equal in all three skins 2SinA = sinB (I think). For example: if A = 12degrees then B = 24.6degrees. Equal tension in all skins may not be necessary however being as we have variable loading. I don’t really understand the issues here, but I thought it would be worth mentioning. The maths seems to fit my intuitive feelings for the proportions, but what do artists know about engineering?

Supper Efficient Variation for Extreme Cold Climates

If another ‘closure baffle’ was installed in the bottom cavities then these cavities could also be used to contain bubbles at night. Using cold bubbles in the top cavity and warmer bubbles in the bottom. This however, would require twice as many bubble generators, but that’s all it would seem. The bottom cavity could still be used in cooling/collection mode during the day.

Snow Load

To distribute stress into middle skin it seems a compression members would be required along the walls of rain water gutter void.

Rain load shared equally between top and middle skin. Bottom skin loses tension.

Top Tie Wrap Tensioner and Leaf Grill

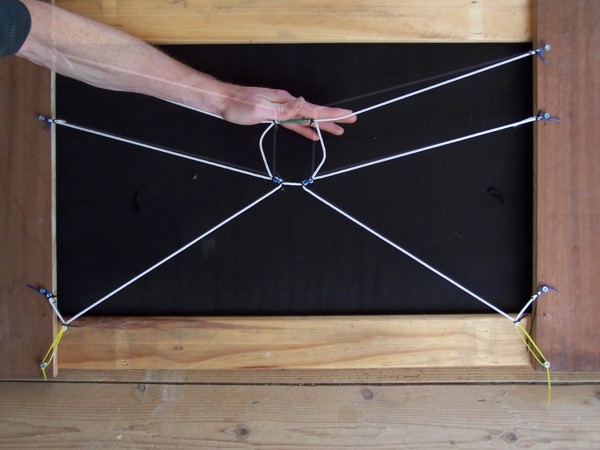

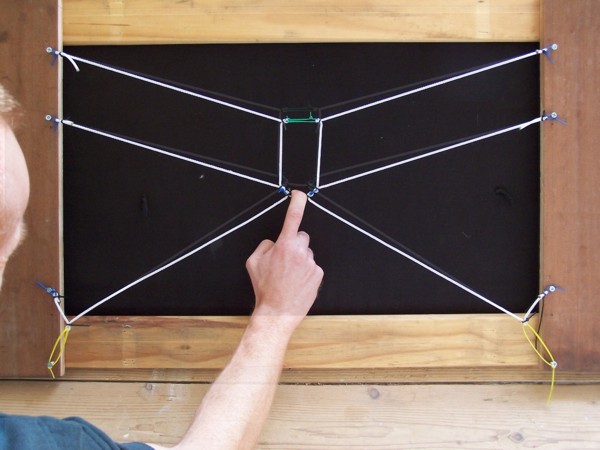

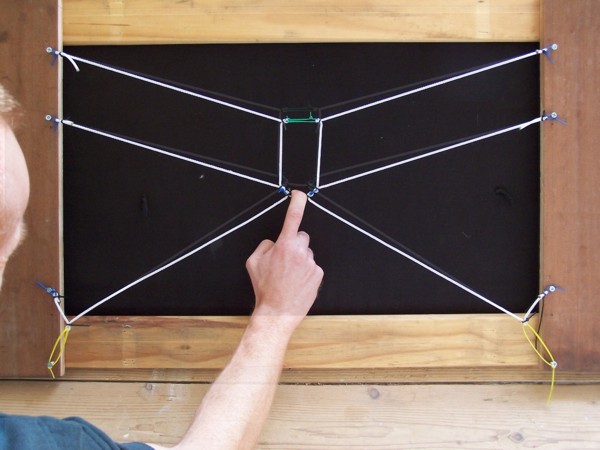

Having played with this string model, the top tensioner seems unnecessary. If the walls of the rain gutter are parallel and vertical then the stress will be equally shared between the top and middle skin. If this is the case then may be the leaf grill material can be used to bridge this gap.

Rain Water Gutter Load

Rain load shared equally between top and middle skin. Bottom skin loses tension.

Top Tie Wrap Tensioner and Leaf Grill

Having played with this string model, the top tensioner seems unnecessary. If the walls of the rain gutter are parallel and vertical then the stress will be equally shared between the top and middle skin. If this is the case then may be the leaf grill material can be used to bridge this gap.